- Get link

- Other Apps

Blog By Homework Buddy

- Get link

- Other Apps

EXPERIMENT 1 (A)

OBJECTIVE:

To

Measure the dimensions of the given sample using Vernier Caliper.

APPARATUS:

Vernier

Caliper, Given Sample.

DESCRIPTION:

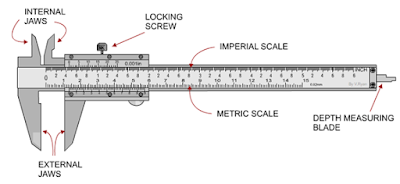

A Vernier caliper

consists of mainly two parts.

i.

A 2cm wide 15cm

long rectangular metal strip. The left end bottom side of this strip consists

of fixed jaw and at the same end jaw at the top of the strip. On the strip a

scale is graduated in inches along the upper edge and another scale is

graduated in centimeters along the lower edge. This is called main scale.

ii.

A metal frame V

called vernier slides over the Main scale. At the bottom of this frame V a

button is attached, which helps to fix this vernier at any desired place on the

main scale. This vernier frame jaws at the bottom and a jaw at the top. Two

scale are graduated on this frame corresponding to two scales on the main

scale. The two scales on the verneir are called Verneir scales. Verneir scales consists of equal

number of divisions.

The

lower jaws are used to measure the thickness or external diameter of the tubes

, cylinders or spheres.

The

upper jaws are used to measure the inner diameter of hollow bodies like tubes

or holes. The thin strip is used to measure the depth of the objects like the

tubes.

THEORY:

Principle of Vernier

Caliper-N division on the Vernier scale is equal to division on the main scale.

N (V.S.D) = (N-1) M.S.D

1 V.S.D = (N-1/N) M.S.D

Least count (L.C) of

Vernier calipers: Minimum length or thickness measurable with the Vernier

caliper is called its least count.

Least count (L.C) = 1

M.S.D – 1 V.S.D

L.C = 1 M.S.D –

(N-1/N)M.S.D

L.C = 1 M.S.D [1-

N-1/N]

L.C = 1M.S.D/N = S/N

Where S is the value of

one Main scale division and N is the number of equal division on the Vernier

scale.

PROCEDURE:

i.

First we have to determine the least

count of the given Vernier caliper.

ii.

To determine the volume of cylinder we

have to determine

a) The

length of the cylinder

b) Radius

of cylinder

And substituting these values in the

equation for the volume of the cylinder we can calculate it.

A. To determine the LENGTH of The

CYLINDER:

Give

cylinder is held gently b/w jaws of Vernier caliper. The reading on the main

scale just before the zero of the Vernier is noted. This is called main scale

reading. The number of division on the Vernier which coincides perfectly with

any one of the main scale divisions is noted. This is called the Vernier

coincidence. The Vernier coincidence (V.C= n) is multiply by least count to get

the fraction of a main scale division. This is added to the main scale reading

(M.S.D) to total reading or total length of the cylinder.

Total reading = M.S.R +

(V.C*L.C)

Take the reading,

keeping the cylinders b/w jaws at different positions. Post the values of M.S.R & Vernier coincidence in the table.

B. To determine the DIAMETER of the

CYLINDER:

Place

the cylinder diametrically b/w the jaws of vernier, as in above case post the

values of M.S.R &vernier coincidence in the table. Take at least 5

readings, calculate the average of these readings which gives the mean diameter(d=2r)

of the cylinder.

C. To determine the VOLUME of The

CYLINDER:

Substituting

the values of the mean length of the cylinder &mean diameter of the

cylinder which is already determined, in the formula V = πr2Lcm3

OBSERVATIONS:

·

Least count of the vernier caliper:

1) Value

of 1 Main scale division = 1M.S.D = S= ………cm

2) Number

of division on the vernier scale N =………….cm

Least count L.C =S/N =……..cm

3) Zero

error = x (positive error)

·

Volume

of the cylinder:

o

Length of the cylinder

S.NO.

|

M.S.R

(cm)

|

Vernier

Coincidence

|

Fraction

B=

(n-x)*L.C

|

Total

Reading

(a+b) cm

|

1

|

2.6

|

9

|

0.09

|

2.69

|

2

|

2.7

|

1

|

0.01

|

2.71

|

3

|

2.7

|

2

|

0.02

|

2.72

|

4

|

2.7

|

2

|

0.02

|

2.72

|

5

|

2.6

|

8

|

0.08

|

2.68

|

Average length of The

cylinder L = 2.70 cm

o

Diameter of the cylinder

S.NO.

|

M.S.R

(cm)

|

Vernier

Coincidence

|

Fraction

B=

(n-x)*L.C

|

Total

Reading

(a+b) cm

|

1

|

1.4

|

5

|

0.05

|

1.45

|

2

|

1.4

|

4

|

0.04

|

1.44

|

3

|

1.4

|

6

|

0.06

|

1.46

|

4

|

1.4

|

5

|

0.05

|

1.45

|

5

|

1.4

|

6

|

0.06

|

1.46

|

Average diameter of the

cylinder = 2r = 1.45 cm

Mean radius of the

cylinder r = d/2

Volume of the

cylinder V = πr2Lcm3

EXPERIMENT 1 (A)

OBJECTIVE:

To

Measure the dimensions of the given sample using Screw Gauge.

APPARATUS:

Screw Gauge,

Given Sample.

DESCRIPTION:

The screw gauge is an instrument

used for measuring accurately the diameter of a thin wire or the thickness of a

sheet of metal. It consists of a U-shaped frame fitted with a screwed

spindle which is attached to a thimble.Parallel to the axis of the thimble, a

scale graduated in mm is engraved. This is called pitch scale. A sleeve is

attached to the head of the screw.

The head of the screw has a

ratchet which avoids undue tightening of the screw. On the thimble there is a

circular scale known as head scale which is divided into 50 or 100 equal parts.

When the screw is worked, the sleeve moves over the pitch scale.

A stud with a plane end surface

called the anvil is fixed on the ‘U’ frame exactly opposite to the tip of the

screw. When the tip of the screw is in contact with the anvil, usually, the

zero of the head scale coincides with the zero of the pitch scale.

Zero Error and Zero

Correction

To get the correct

measurement, the zero error must be taken into account. For this purpose, the

screw is rotated forward till the screw just touches the anvil and the edge of

cap is on the zero mark of the pitch scale. The Screw gauge is held keeping the

pitch scale vertical with its zero down wards.

When this is done,

anyone of the following three situations can arise:

- The zero mark of the circular

scale comes on the reference line. In this case, the zero error and the

zero correction, both are nil.

- The zero mark of the circular

scale remains above the reference line and does not cross it. In

this case, the zero error is positive and the zero correction is negative

depending on how many divisions it is above the reference line.

- The zero mark of the head scale is below the reference line. In this case, the zero error is negative and the zero correction is positive depending on how many divisions it is below the reference line.

PROCEDURE:

·

Determine the

pitch and least count of the screw gauge using the equations (1) and (2)

respectively..

·

Bring the anvil

and screw in contact with each other and find the zero error. Do it three times

and record them. If there is no zero error, then record ‘zero error nil’.

·

Move the screw

away from the anvil and place the lead shot and move the screw towards the

anvil using the ratchet head. Stop when the ratchet slips without moving the

screw.

·

Note the number

of divisions on the pitch scale that is visible and uncovered by the edge of

the cap. The reading N is called the pitch scale reading(PSR)

·

Note the number

(n) of the division of the circular scale lying over the reference line.

·

Repeat steps 4

and 5 after rotating the lead shot by 900 for measuring the diameter in a

perpendicular direction. Record the observations in the tabular column.

·

Find total

reading using the equation 3 and apply zero correction in each case.

Ø To find the thickness of the glass

plate:

The glass plate is gripped

between the tip of the screw and the anvil. The PSR and HSR are noted as

before.

The thickness of the glass plate

is;

t = PSR+ corrected HSR = N + (n x L.C)

Ø To find the diameter of the wire:

Place the wire

between the anvil and the screw and note down the PSR and HSR as before.

The diameter

of the wire is given by;

T.R = PSR+ (corrected HSR x L.C) = N + (n x L.C)

If r is radius

of the wire, and l be the mean length of the wire.

Then, volume

of the wire,

THICKNESS

OF THE GLASS PLATE

S.NO.

|

Pitch Scale reading (P.S.R)

|

Observed

H.S.R

|

Correction

|

Corrected H.S.R

|

Fraction

B= n*L.C

|

Total

reading

|

1

|

2

|

75

|

2

|

73

|

0.73

|

2.73

|

2

|

2

|

74

|

2

|

72

|

0.72

|

2.72

|

3

|

2

|

76

|

2

|

74

|

0.74

|

2.74

|

Average thickness of

glass plate = 2.73 mm

- Get link

- Other Apps

My hopes are to secure a challenging role to help students.During my degree, I have developed an excellent eye for detail, due to the heavy demands of assignments and research. As a result, I am also able to work under pressure.

I'll try to make you an ‘extremely driven strategic thinker with excellent skills and extensive experience.

Comments

I enjoyed your work and the manner in which you presented this article on Gauge. For us, it is a beneficial and useful paper. Thank you for sharing this story.

ReplyDeleteTank Level Gauge

Thanks alot

ReplyDeletegood

ReplyDeleteloving your steps of writing . it help me a lot in IIT DELHI . thanks bro

ReplyDelete